A factor of 200 reduction of iridium catalyst for PEM electrolysers is demonstrated to be possible keeping on average 1/3 of performance

24-10-2022

This decade Alkaline and PEM will be the dominant electrolyser technologies

Green hydrogen is expected to play a major role in the energy transition in order to integrate huge amount of renewable electricity, decarbonize the heavy industry such as steel and highly emitting mobility such as aviation and for seasonal storage of hydrogen in the subsurface. This green hydrogen needs to be produced using water electrolyser technology. At this moment there are two main mature technologies: the Alkaline and PEM (Polymer Electrolyte Membrane) electrolyser. These two will dominate the market, at least for the coming decade. For both technologies the main cost drivers are efficiency and capital cost. Efficiency in terms of the electricity needed to produce a kilogram of hydrogen (targets 2024 for respectively PEM and Alkaline are 52-49 kWh/kg) and capital cost of the actual investment of the electrolyser (targets 2024: 700- 480 Euro/ kW)1. For the reduction of the use of critical raw catalyst materials there are also targets formulated by the EU Clean hydrogen joint Undertaking, however more attention by industry is needed to actually reach these targets.

Will the availability of critical raw material be a showstopper for electrolyser technology?

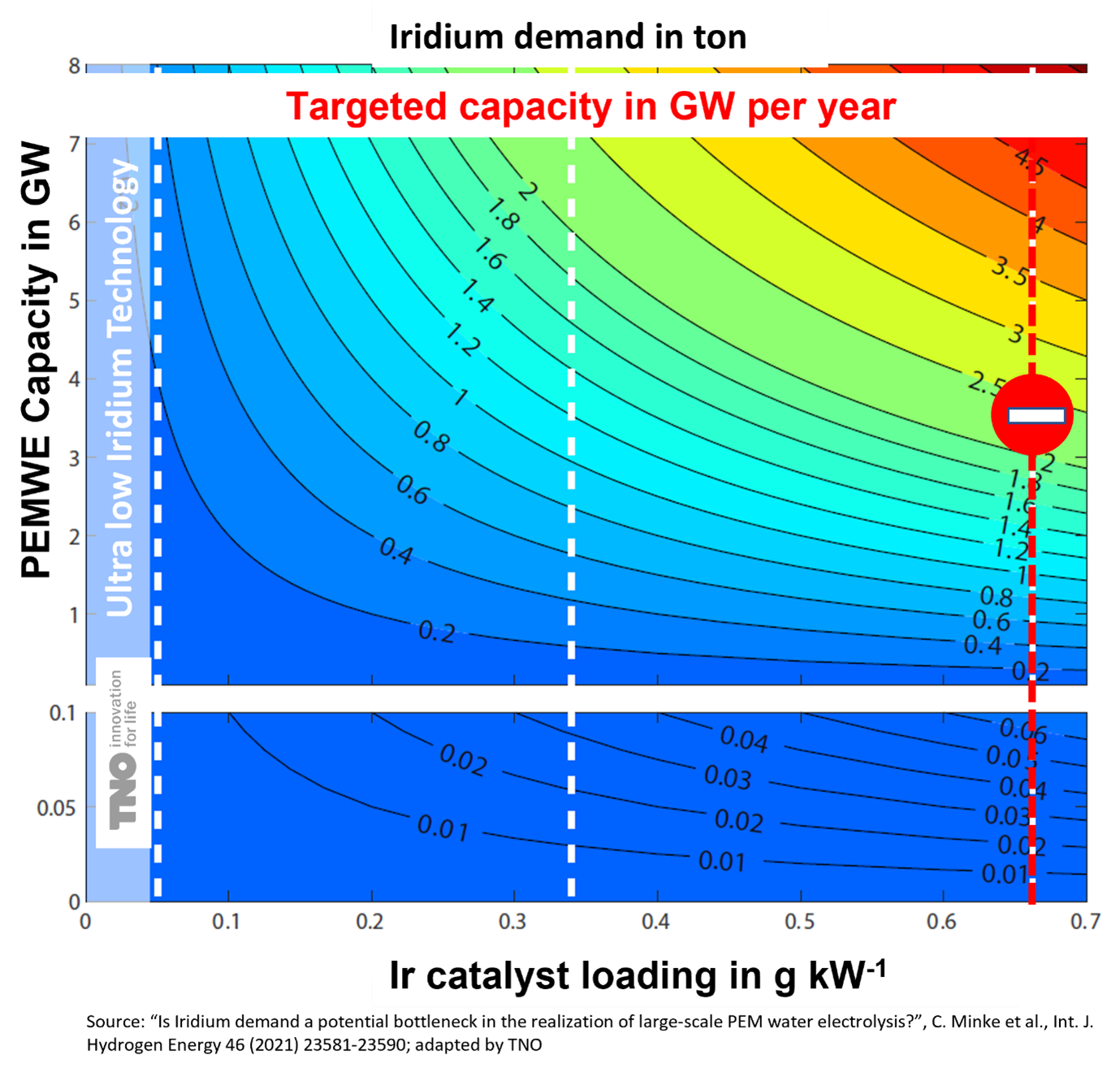

A recent TNO publication2 answers the following questions: How raw materials scarcity can hinder our ambitions for green hydrogen? and Can we prevent the scarcity of raw materials and achieve our ambitions? Iridium is the element with the least Earth’s crust abundance of all3 and a typical secondary mining product along the primary mining of Platinum. Iridium serves as a catalyst for the Oxygen Evolution reaction due to its good trade-off between activity and stability, i.e., withstanding harsh acidic water splitting conditions in the PEM electrolyser4. The iridium world mining production in 2018 was around 7 tons/year5 (~2 tons/year assumed for use in electrochemical applications). Assuming that about 40% of PEM electrolysers (and 60% of alkaline electrolysers, neglecting the other type of electrolysers as viable options before 2030) are required for EU’s targeted 40 GW electrolyser capacity in 2030 means that the iridium demand in tons would become too large compared to the yearly mined amount: taking into account the current iridium catalyst loading of 0.67 g kW-1 (dotted line on the right of the Figure below) under an installation rate of only 100 MW in 2020 would require an amount of 67 kg or iridium (~1% of yearly worldwide Ir mining). However, ramping up towards the EU’s targeted capacities, would mean increasing to installing about 5 GW/year. Then the annual iridium demand would increase to 3.35 tons/year (47% of globally mined Ir / year) which means a no go for the PEM electrolyser based on current Iridium availability.

Especially when taking into consideration the challenges in the supply chain: South Africa accounts for 85% of global iridium mine supply, which was severely disrupted due to COVID-19 (partially leading to the sharp cost increase). These supply chain issues will stay, as Russia is also an important supplier, while demand is expected to rise also in the electronics market, e.g., in smartphones6. This shows the criticality of decreasing iridium amounts in the PEM electrolyser as well as the importance of being able to recycle in Europe and becoming less dependent on the distorted supply chains.

Iridium demand from catalyst loading and PEM electrolyser capacity on large industrial scale with catalyst loading of 0.67 g kW-1 (2020 status with red dotted line5 and catalyst loading below 0.01 g kW-1 (white left dotted line). The contour lines represent levels of resulting iridium demand in tonnes. White box indicates the targeted production capacity per year required to obtain 40 GW electrolyser capacity in 2030.

3rd Generation PEM electrolysers with ultra-low iridium loading

To make PEM technology a viable option for the electrolyser capacity upscaling towards 40 GW in Europe in 2030 a drastic decrease of iridium is needed. The TNO scientists successfully executed a number of experiments in the last two years resulting in a breakthrough patented technology. Experts from TNO Holst Centre employed Spatial Atomic Layer Deposition (ALD) in order to realize an ultra-thin porous iridium catalyst layer in PEM stacks. In the TNO Faraday Lab the stability of the resulting new electrolyser cell was demonstrated with a so called ‘accelerated stress test protocol’ to test the cell under extremely harsh conditions. After this validation test there was hardly any degradation. This outcome is promising and therefore TNO will work together with industrial partners to accelerate this development and bring this technology to the market before 2030. We need to join forces with the industry to jointly overcome a number of technical hurdles. Next step is to prove that the technology will work on a larger electrolyser cell area, that the degradation is limited over a longer life time, and that we can increase the efficiency of the cell towards the state of art level of PEM electrolysis.

TNO Holst Centre

TNO Faraday Lab Petten

[1] Clean hydrogen joint Undertaking (2022), Strategic Research and Innovation Agenda 2021 – 2027 (link)

[2] TNO (2021), Part 1 - How raw materials scarcity can hinder our ambitions for green hydrogen and the energy transition as a whole (link), Part 2 - How we can prevent the scarcity of raw materials and achieve our ambitions for green hydrogen

[3] https://pubs.usgs.gov/fs/2002/fs087-02/

[4] “Activity-stability trends for the oxygen evolution reaction on monometallic oxides in acidic environments”, N. Danilovic et al., JPCL 5 (2014) 2474-2478

[5] “Is Iridium demand a potential bottleneck in the realization of large-scale PEM water electrolysis?”, C. Minke et al., Int. J. Hydrogen Energy 46 (2021) 23581-23590

[6] Geopolotics of the Energy Transformation, The Hydrogen Factor

Share this page: