Pleased to meet: Elena Pérez Gallent

01-06-2023 | P2Chemicals

LEAD SCIENTIST POWER-2-CHEMICALS

In this series, we put the spotlight on VoltaChem’s team members and get to know them more in-depth. We explore their role, background, expertise, motivations and ambitions. In this edition: Elena Pérez Gallent, Lead Scientist Electrosynthesis of the Power-2-Chemicals program line at VoltaChem.

In this series, we put the spotlight on VoltaChem’s team members and get to know them more in-depth. We explore their role, background, expertise, motivations and ambitions. In this edition: Elena Pérez Gallent, Lead Scientist Electrosynthesis of the Power-2-Chemicals program line at VoltaChem.

Elena Pérez Gallent is a motivated and goal-driven researcher with a background in electrochemistry, catalysis and analytical chemistry. She started her education in chemistry at the University of Valencia, finished her MSc at Leiden University (2012) and obtained her PhD (2018) also at Leiden, focusing on electrochemical conversion techniques such as carbon dioxide electrolysis. In May 2018 Elena joined TNO as an electrochemical research scientist, and since January 2023 she is Lead Scientist in Power-2-Chemicals program line at VoltaChem.

How did you end up at TNO?

I have been working on the same subject, CO2 electrolysis, since 2011. After I completed my PhD research, I wanted to continue working in the same field of interest. So I started looking for a place where I could implement this technology. TNO seemed very attractive to me. I saw a post on LinkedIn about the mission of the Shared Innovation Program VoltaChem, to support the chemical industry, the energy sector, and equipment suppliers & licensors to move towards a climate-neutral future. Finding collaborative business opportunities and addressing their challenges together by linking flexible electricity supply to energy demand in the chemical industry and by using electricity directly in chemical processing, employing novel technologies and business models. For me there was no doubt, I knew I had to work there.

What does your job at VoltaChem involve?

As a Lead Scientist, I’m responsible for one of VoltaChem’s program line, Power-2-Chemicals. In the Power-2-Chemicals program line, we work on the direct electrosynthesis of chemical building blocks and higher-value products using conventional and sustainable feedstock (e.g. CO2, biomass-derived). The main challenges that are addressed are the development of electrochemical routes, reducing capital costs for electrochemical cells, increasing energy density and selectivity, choosing & using catalysts, and downstream processing. I’m thinking about which path we have to take, and which technologies we should develop to achieve this. It is important that I am aware of the latest developments within Power-2-X and what trends are emerging. Then, we can determine where we want to go and how to get there and develop a roadmap for the future. My daily work is very diverse, I for example guide some colleagues that work in the lab, write project applications for Dutch or European subsidy calls and make sure I keep an overview of what we do within the program line.

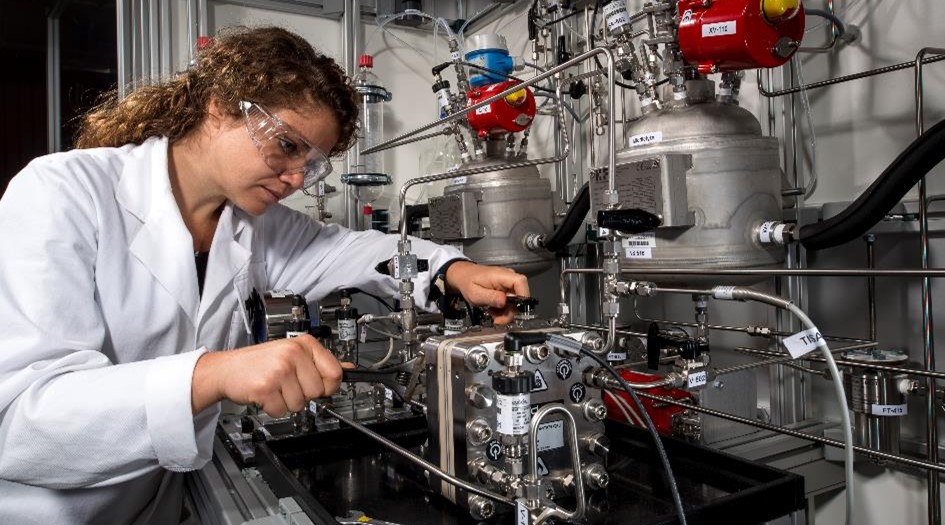

Elena Pérez Gallent at work in the lab, TNO Delft.

I like my job very much. It feels good to be busy with something truly important. I do many different things and that ensures that my working day is never boring and very dynamic. Being involved in science, business and program management is very interesting and rewarding. I like the way we work together with people from other disciplines. With our multidisciplinary approach, we bring different perspectives together and learn from each other. That has so much added value.

Elena giving a presentation on CO2 utilisation at the CO2-based fuels and chemicals conference in Cologne, April 2023.

What are the biggest challenges in your line of work?

One of the biggest challenges is scaling up. Many electrolysis studies are performed on a small scale. A lot of fundamental work is done at universities, and that is much needed. With that knowledge, we can understand where the challenges and opportunities lie. There is, however, a gap between what universities do and implementation on an industrial scale. That’s where VoltaChem comes in. The development step from the controlled environment of the lab to an industrially relevant scale, which is no longer that controlled, is a big one. How do we ensure that catalysts are stable under non-lab conditions? How do we integrate every unit needed in the whole process? How do we improve the economics of the process by developing novel concepts? We’re dealing with that sort of questions.

How do you envision the future of electrolysis?

Some people have some concerns about electrolysis. And yes, it is expensive, but the switch from fossil to sustainable alternatives is always more expensive. I think we should move towards a combination of sustainable technologies. Different technologies will have to be used together, side by side, to be able to get rid of fossil raw materials and fuels. What should be used where depends on the situation. We now have to focus on developing them all, not see them as competitors, and map them in the right industries when the time is right. But of course, I see a bright future for electrolysis. It is a clean technology and can become economically feasible in the future. It’s one of the key players in the transition of industry. The ultimate goal is to make molecules out of CO2, water and nitrogen from the air. But that will take a while. Now is the time to take the first steps towards that goals. And that doesn’t only involve technological challenges but also dissemination of information to the public to create awareness and acceptance of upcoming challenges, changes and costs.

You have been in the Netherlands since 2011. Are you here to stay?

I ended up in the Netherlands because I came across the Erasmus student exchange program. I thought it would be very valuable to study abroad and gain experience in my field. Friends of mine moved to Leiden a year earlier and they liked it here. That’s how I ended up in Leiden. The Netherlands is a lovely country, full of opportunities and more importantly, there is quite some attention to researching environmentally sustainable topics. Yes, I am here to stay for some more years.

Share this page: